Tessellation of carbon fibre grid reinforcements | Funding Period 2

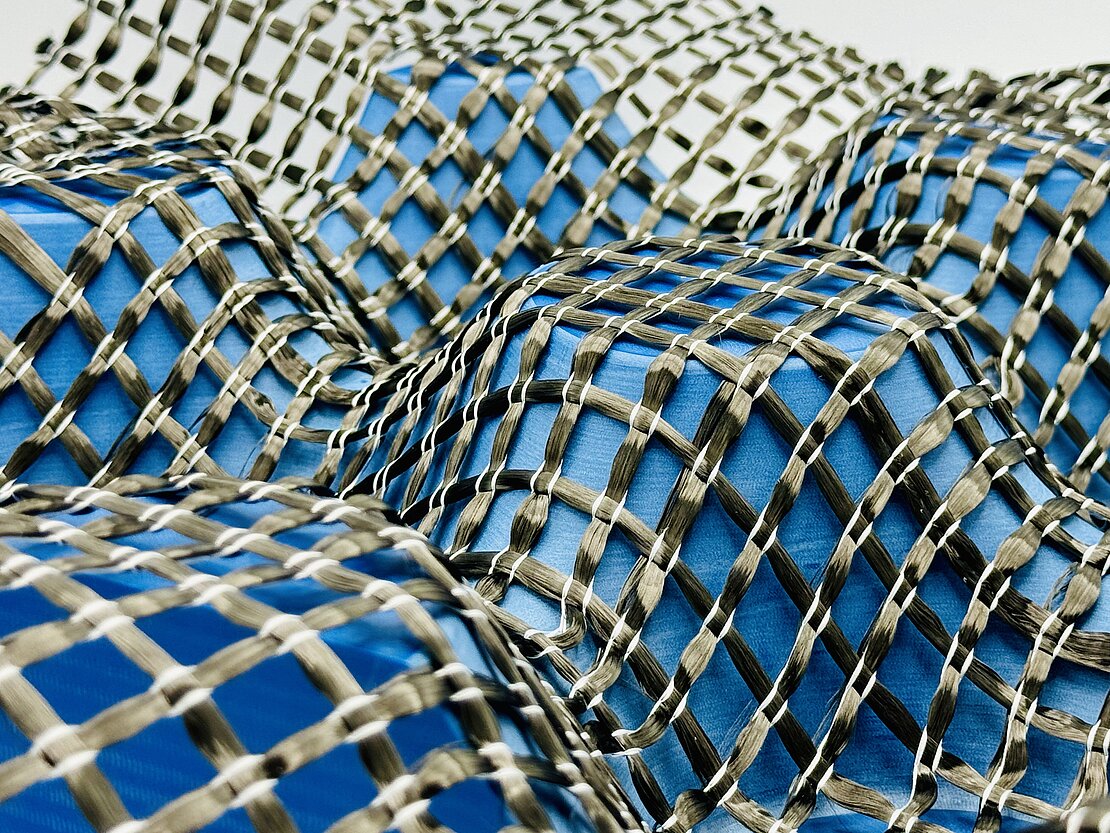

The architecture of the textile reinforcement allows its properties such as strength, bending stiffness, and draping behavior to be determined during the manufacturing process. After the textile structure has been produced, these properties can be further influenced by a variety of finishing processes and the textile systems can be functionalized. Our aim is to enable novel approaches to the shaping of textile fabrics in order to extend the achievable shapes of carbon-reinforced concrete elements through tessellation. Tessellation describes the construction of periodically repeating patterns that are built up from simple basic geometric shapes. In order to realize these complex geometries flexibly and at the same time achieve good mechanical properties of the reinforcement, the approaches investigated in period 1 of TRR 280 – time-delayed curing in the prepreg approach or thermally induced softening in the organosheet approach – are applied.

The central aspect of the research is the analysis of the dependencies of manufacturing and structural parameters of the textile reinforcement on the draping behavior. Particular attention is paid to shear, compression and lane formation in the curvature area of the tessellation and the mechanical behavior under tensile and compressive load. In addition to research on the material side, manufacturing approaches for large-scale mosaic-like reinforcement structures are also being investigated.

Scientists

D-52074 Aachen (Germany)

![Dr.-Ing. Kira Heins [Translate to English:]](/fileadmin/_processed_/0/3/csm_B_Heins_Kira_quadratisch_kl_e2875551b8.jpg)

D-52074 Aachen (Germany)

52074 Aachen (Germany)

52074 Aachen (Germany)

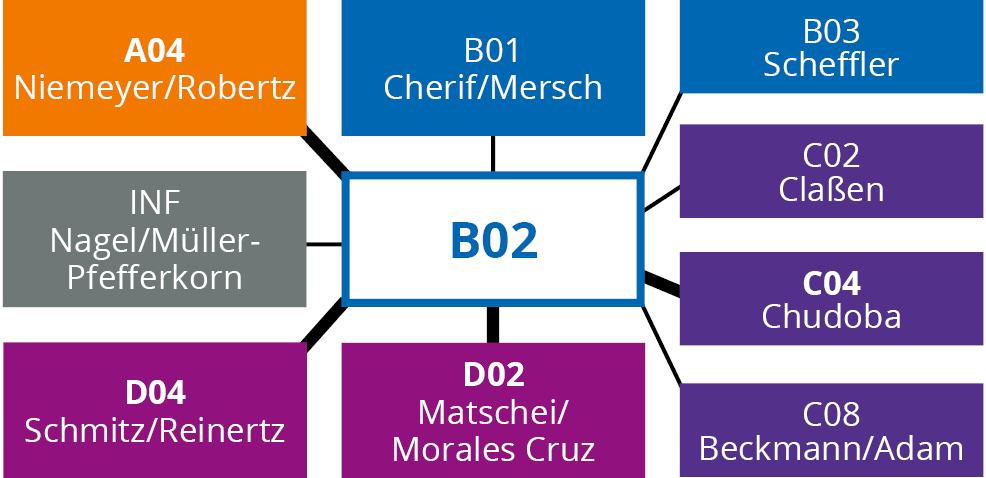

Cooperations

Ehemalige | Former involved

Martin Scheurer (research associate, RWTH Aachen, 07/2020 – 07/2024)

Investigation of New Material and Technology Approaches for Continuous Inline-Forming and Consolidation of Textile Reinforcements | Funding Period 1

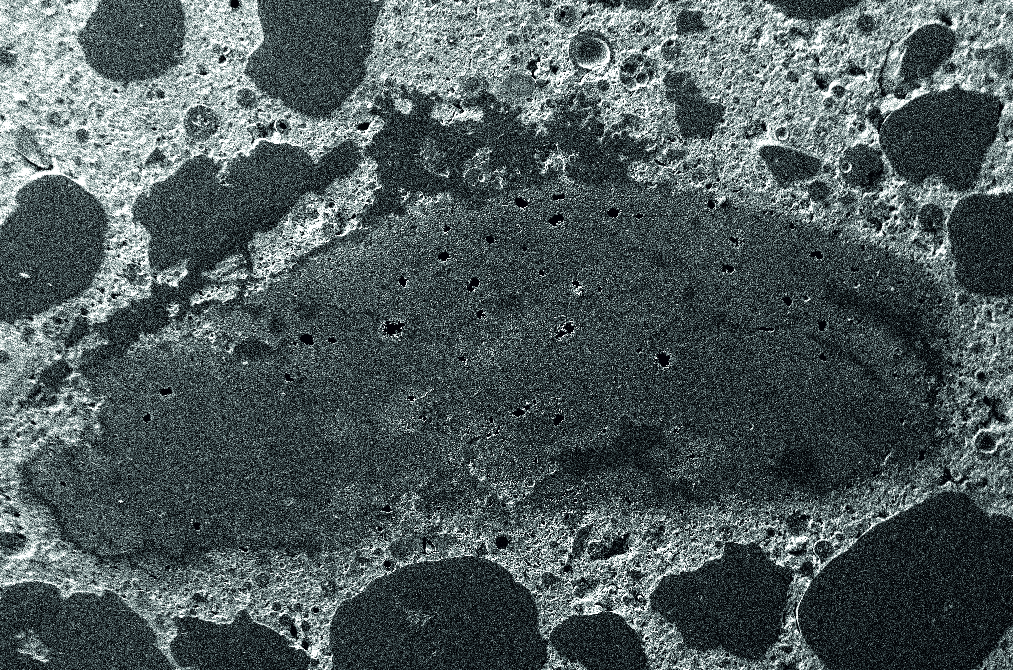

New, digital and continuous production methods (e.g. 3D concrete printing and concrete extrusion) allow for load-path-adapted (form follows force) and thus material-minimized constructions. However, conventional impregnated textile reinforcements are not suitable for integration into these manufacturing processes for the production of complex carbon-reinforced concrete structures. The main reason is the loss of a large part of the form flexibility due to the established offline consolidation. Project B02 therefore investigates the targeted temporal shift of the forming and consolidation step using prepreg systems into the concreting process and its applicability in the course of the new, digital and continuous manufacturing processes. In addition to established curing mechanisms such as heat or UV radiation, new approaches, such as activation via the alkalinity of the concrete, microwaves and induction, for inline production of carbon-reinforced concrete are investigated.

Within the framework of B02, the seed fund project "Carbon-reinforced concrete structures additively manufactured on free-standing textile formwork – freeDome" (1st round 2022) is carried out together with project D01.

Publikationen | Publications

Backes, J. G. M.; Scheurer, M.; Kalthoff, M.; Gries, M.; Matschei, T.; Raupach, M.; Traverso, M. (2022) Sustainability of textile reinforcements for carbon concrete – today and tomorrow in: Stokkeland, S.; Braarud, H. C. [eds.] Concrete Innovation for Sustainability – Proc. for the 6th fib International Congress 2022, 12.–16.06.2022 in Oslo (Norway), Oslo: Novus Press, p. 2130–2138.

Friese, D.; Scheurer, M.; Hahn, L.; Gries, T.; Cherif, Ch. (2022) Textile reinforcement structures for concrete construction applications—a review in: Journal of Composite Materials 56, issue 26, p. 4041–4064 – DOI: 10.1177/00219983221127181

Heins, K.; Lesker, S.; Pütz, J.; Hüntemann, M.; Gries, T. (2023)Effect of thermoplastic impregnation on the mechanical behavior of textile reinforcement for concrete in: SN Appl. Sci. 5, 93 – DOI: 10.1007/s42452-023-05305-y

Scheurer, M.; Dittel, G.; Heins, K.; Gries, T. (2023) Polymer Impregnated Textile Reinforcement Cured in Concrete by Means of Electric Heating in: Harris, K. A.; Cardoso, D. C. T.; da Silva, F. A. [eds.]: Proc. of 11th Int. Conf. on Fiber-Reinforced Polymer (FRP) Composites in Civil Engineering (CICE 2023), 24.–26.07.2023 Rio de Janeiro (Brazil), 2023 – https://doi.org/10.5281/zenodo.8139441

Scheurer, M.; Dittel, G.; Kalthoff, M.; Raupach, M.; Matschei, T.; Gries, T. (2023) Evaluation of Properties of Impregnated Reinforcement Textiles Cured Within Concrete for Applications in Concrete Extrusion in: Ilki, A.; Çavunt, D.; Çavunt, Y. S. [eds.] Building for the Future: Durable, Sustainable, Resilient – Proc. of fib Symposium 2023, 05.–07.06.2023 in Istanbul (Turkey), publ. in: Lecture Notes in Civil Engineering 349, Cham: Springer, p. 1293–1302 – DOI: 10.1007/978-3-031-32519-9_131

Scheurer, M.; Friese, D.; Heins, K.; Hahn, L.; Mersch, J.; Cherif, C.; Gries, T. (2024) Novel Textile Reinforcements for Advanced Concrete Production Methods in: Mechtcherine, V.; Signorini, C.; Junger, D. [eds.]: Transforming Construction: Advances in Fiber Reinforced Concrete – Proc. of XI RILEM-fib Int. Symp. on Fiber Reinforced Concrete (BEFIB 2024), 15.–18.09.2024 in Dresden, publ. in RILEM Bookseries, Vol. 54, Cham: Springer Nature Switzerland, p. 778–785 – https://doi.org/10.1007/978-3-031-70145-0_92

Scheurer, M.; Friese, D.; Penzel, P.; Dittel, G.; Bhat, S.; Overhage, V.; Hahn, L.; Heins, K.; Cherif, C.; Gries, T. (2023) Current and future trends in textiles for concrete construction applications in: Textile 3, issue 4, p. 408–437 – https://doi.org/10.3390/textiles3040025

Scheurer, M.; Gries, T. (2022) Investigation of new material and technology approaches for continuous inline-forming and consolidation of textile reinforcements for concrete in: Gries, T.; Röding, T.; Pohlkemper, F.; Liu, Z.; Böhler, P.; Haag, M. [eds.] Aachen Reinforced! Symposium 2022, 17.–19.10.2022 in Aachen, p. 24–27.

Scheurer, M.; Gries, T. (2023) Comparative evaluation of textiles for use in textile reinforced concrete contribution to 2nd Int. Conf. on Construction Materials and Structures (ICCMS-2022), 14.–18.12.2022 at National Institute of Technology Calicut Kerala, Kerala (India, online), publ. in: Materials Today Proceedings – https://doi.org/10.1016/j.matpr.2023.03.477

Scheurer, M.; Kalthoff, M.; Matschei, T.; Raupach, M.; Gries, T. (2022) Analysis of Curing and Mechanical Performance of Pre-Impregnated Carbon Fibers Cured within Concrete in: Textiles 2, issue 4, p. 657–672 – DOI: 10.3390/textiles2040038

Scheurer, M.; Neef, T.; Dittel, G.; Mechtcherine, V.; Gries, T. (2023) Textile Reinforced Concrete Structures Additively Manufactured on Free-Standing Textile Formwork in: Harris, K. A.; Cardoso, D. C. T.; da Silva, F. A. [eds.]: Proc. of 11th Int. Conf. on Fiber-Reinforced Polymer (FRP) Composites in Civil Engineering (CICE 2023), 24.–26.07.2023 Rio de Janeiro (Brazil), 2023 – DOI: https://doi.org/10.5281/zenodo.8114263

Studentische Arbeiten | Student’s works

Faust, M. (2023) Recherche zur Aushärtung der Tränkungsmatrix von Carbonbetonbewehrungen mittels Induktion [Forschungslabor | research laboratory]

Örsak, Y.; Saatcioglu, O. (2023) Recherche und Bewertung von Aushärtungsmechanismen für imprägnierte Carbonfasertextilien in Beton [Projektarbeit | project work]

Walter, E. S. (2023) Experimentelle Untersuchungen zur Ermittlung des Einflusses der Carbonfaserschlichte auf die Faser-Matrix Haftung von Textilbeton [Bachelorarbeit | Bachelor's thesis]

Behnke, L. (2022) Feasibility Study of Curing Preimpregnated Carbon Fibres in Textile-Reinforced Concrete by Means of Electric Heating [Bachelorarbeit | Bachelor's thesis]

Müllerschön, P. (2022) Untersuchung zur Aushärtung von Tränkungen vorimprägnierter Carbonfasern im Beton für den Extrusionsprozess [Masterarbeit | Master's thesis] (mit | with D02)

Nguyen, T. L. (2022) Anforderungen an Geometrie und Formgebung bei Textilbetonelementen [Bachelorarbeit | Bacgelor's thesis] (mit | with D02)

Yuan, F.; Müller, H.; Xia, J. (2022) Prozessanalyse: Formung von Textilbewehrungen [Projektarbeit | Projct work]

Hartig, C. (2021) Experimentelle Analyse der Aushärtung und Verbundeigenschaften [Masterarbeit | Master's thesis] (mit | with D02)

Köymen, T. S.; Basaran, M.; Yilmaz, A. (2021) Experimentelle Untersuchungen der Einflüsse verschiedener Schlichten auf die mechanischen Kennwerte bei Carbonbeton [Projektarbeit | Projct work]

Vocke, K. (2021) How sustainable are concrete reinforcement alternatives? Sustainability assessment of carbon- and glass fiber-reinforced concrete in comparison to conventional steel-reinforced concrete based on Life Cycle Assessment [Masterarbeit | Master's thesis] (mit | with E01)