Extruded ceiling systems

The aim of Transregio 280 is to develop new design principles for the production of carbon-reinforced concrete components with the aid of innovative manufacturing processes such as extrusion. Currently, carbon-reinforced concrete components are usually constructed in such a way that the steel reinforcement is replaced by carbon reinforcement. The components produced in this way are generally realized with less concrete, although familiar construction principles from classic reinforced concrete are usually used. The decision whether to use carbon-reinforced concrete is usually based on the material performance and the normative framework conditions. Aspects of ecological sustainability such as the Global Warming Potential (GWP) have so far only played a minor role in the selection of components. Initial life cycle assessment calculations have shown that known construction principles, which are adopted for carbon-reinforced concrete, do not show any significant reduction in emissions in terms of GWP.

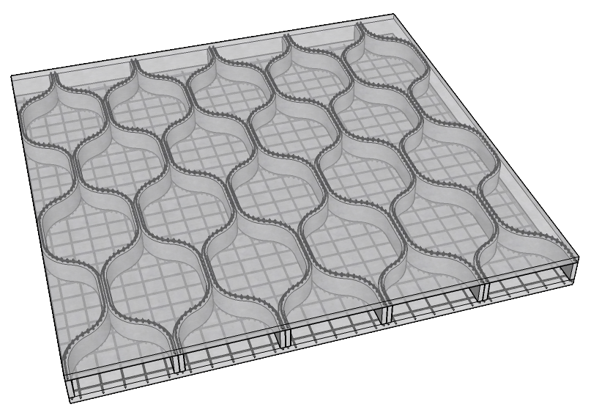

Slender web slabs or hollow core slabs with a high structural effective height and low concrete usage are particularly economical, although they are very expensive to produce. In project D02, it was shown for the first time that new types of hollow core slab elements can also be realized from partially extruded, modularly assembled components with a weight saving of up to 80 % compared to steel-reinforced concrete. However, there was currently a lack of component tests to prove the load-bearing capacity and the further development of functional units suitable for the material as well as the ecological sustainability performance.

Scientists

![Prof. Dr.-Ing. Thomas Matschei [Translate to English:] Thomas Matschei](/fileadmin/_processed_/d/1/csm_2024_D02_Matschei_b2ae8c156b.jpg)

D-52062 Aachen (Germany)

D-52062 Aachen (Germany)

![Prof. Dr.-Ing. Martin Claßen [Translate to English:] Marton Claßen](/fileadmin/_processed_/a/5/csm_A-Classen_Quadratisch_ef8c569abf.jpg)

D-52074 Aachen (Germany)

![Prof. Dr.-Ing. Marzia Traverso [Translate to English:] Marzia Traverso](/fileadmin/_processed_/0/1/csm_Traverso_Quadratisch_e565fbff63.jpg)

D-52074 Aachen (Germany)