Flexible folding of textile-reinforced concrete components | Funding Phase 2

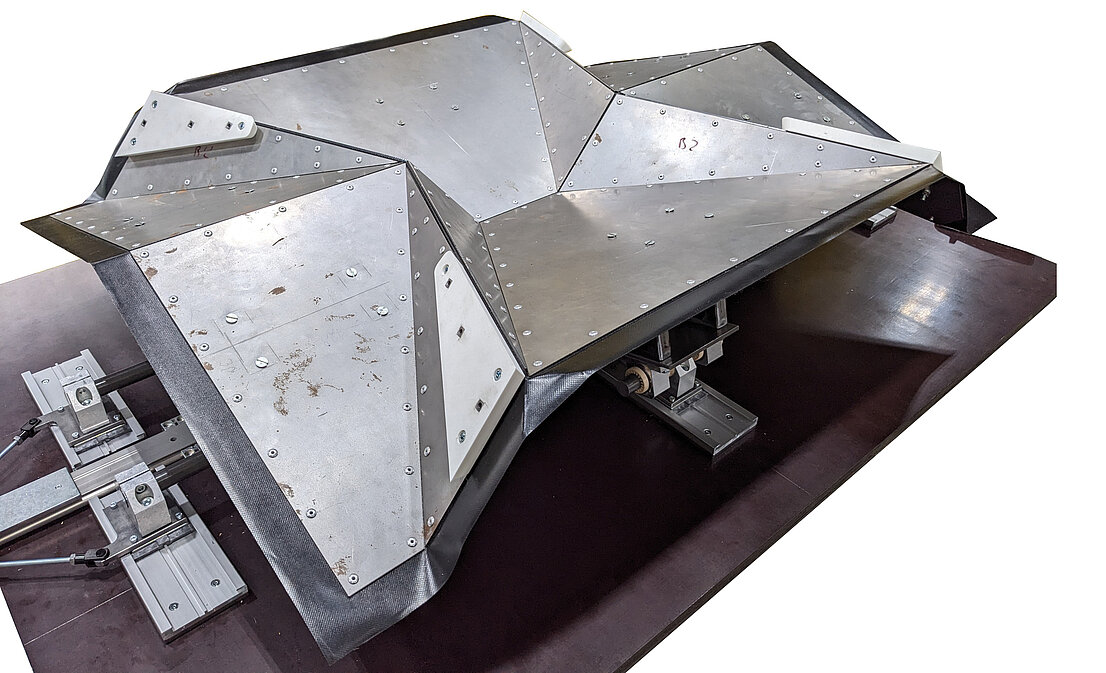

Within the scope of the project D04, methods are to be researched for the automated folding of plane, thin, fresh textile-reinforced concrete into complex component-specific non-orthogonal geometries. This enables sustainable and economical production and should be achieved by integrating a large number of component-specific controlled folding edges in the interface between the tool and the component. This gives rise to various scientific questions, from the joint kinematics and sealing, the behavior of the workpiece during folding, over the mathematical optimization of the position of the folding lines up to the actuation of the tool.

A small test rig with a limited number of facets will be realized to validate simulation models and possible implementations of the tessellated tool surface. In addition, this test rig enables the investigation of the effects of the folding process on the textile-reinforced concrete. The results of the project will be validated using a demonstrator that allows the production of customized folded carbon concrete components and the analysis of the manufacturing process and achievable tolerances.

Scientists

![Prof. Dr.-Ing. Katharina Schmitz [Translate to English:]](/fileadmin/_processed_/2/e/csm_D04_2024_Schmitz_2186cecdf4.jpg)

52074 Aachen (Germany)

52074 Aachen (Germany)

52074 Aachen (Germany)

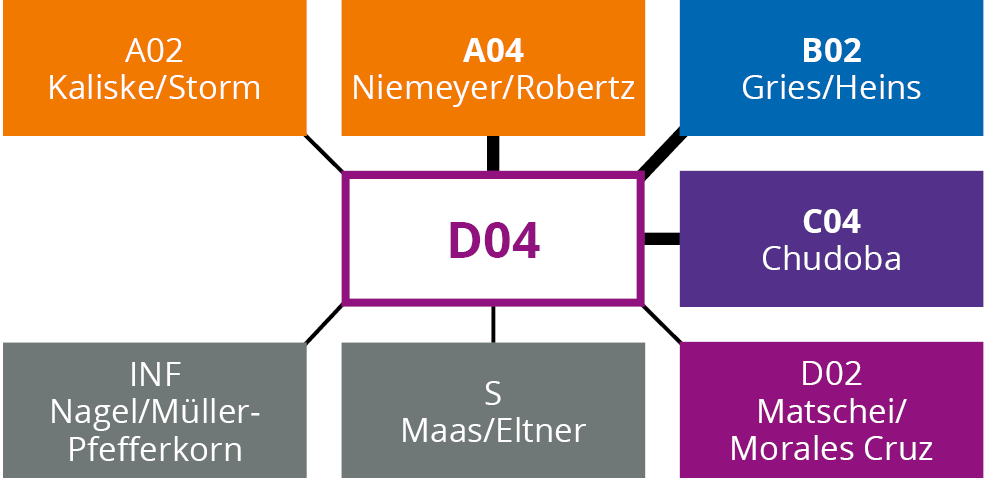

Cooperations

Publikationen | Publications

Bhat, S.; Heins, K. R.; Bertram, C.; Reinertz, O.; Schmitz, K.; Gries, T. (2024) Ein Ausblick auf das Zusammenspiel von Faltprozess und Drapierbarkeit der Textilbewehrung in: Beton- und Stahlbetonbau 119, issue 12, p. 925–935 – https://doi.org/10.1002/best.202400062

Bertram, C.; Beckers, J.; Reinertz, O.; Morales Cruz, C.; Matschei, T.; Schmitz, K. (2025) A Novel Manufacturing Process for Precise Honeycomb Shaping of Extruded Carbon-Reinforced Concrete Elements in: Briffaut, M.; Torrenti, J. M. [eds.] Concrete structures: extend lifetime, limit impacts – Proc. of fib Symposium 2025, 16.–18.06.2025 in Antibes (France), 2025, p. 2754–2765

Gomes, C. G.; Bertram, C.; Reinertz, O.; Schmitz, K.; Chudoba, R. (2025) Flexibility and precision: Manufacturing concept for folded tessellated lightweight carbon-reinforced concrete slabs in: Briffaut, M.; Torrenti, J. M. [eds.] Concrete structures: extend lifetime, limit impacts – Proc. of fib Symposium 2025, 16.–18.06.2025 in Antibes (France), 2025, p. 2682–2693

Studentische Arbeiten | Student's works

Bollmohr, M. (2025) Entwicklung und Erprobung von Gelenken für die Werkzeugoberfläche einer Faltschalung zur Fertigung textilbewehrter Betonelemente [Bachelorarbeit | Bachelor's thesis]

Sickora, S. (2025) Entwicklung eines automatisierten Werkzeugs zum Falten frisch extrudierter Carbonbeton-Elemente in Honigwabengeometrie [Masterarbeit | Master’s thesis]